In today’s hyper-competitive electronics industry, companies that can deliver end-to-end manufacturing and supply chain solutions are the ones defining the future of product innovation and market success. One standout provider in this space is East West Manufacturing, whose comprehensive services span concept-to-scale EMS (Electronic Manufacturing Services), supporting both global brands and emerging innovators with exceptionally integrated design, manufacturing, and logistics expertise. Whether you’re a startup launching your first product or an established enterprise optimizing global operations, these solutions eliminate fragmentation and accelerate time-to-market.

From ideation and prototyping through full-volume production and after-market support, a complete electronics manufacturing and supply chain solution helps brands maintain quality, reduce costs, and ensure sustainability. This article explores the key components of such end-to-end solutions, the critical role of advanced engineering and logistics collaboration, and how strategic partners like East West Manufacturing empower businesses to scale successfully.

What Are End-to-End Electronics Manufacturing and Supply Chain Solutions?

An end-to-end electronics manufacturing and supply chain solution covers every phase of the product life cycle — from early design and engineering to procurement, manufacturing, test, packaging, and distribution. These solutions integrate processes so that each stage is optimized in concert with the others, creating efficiencies that are nearly impossible when managed in silos.

At its core, end-to-end support enables companies to:

- Reduce complexity by consolidating suppliers and processes

- Improve quality control through integrated data and consistent standards

- Accelerate time-to-market with synchronized timelines and rapid iteration

- Scale smoothly from prototype to mass production

- Streamline logistics and fulfillment with robust supply chain management

- Enhance visibility and flexibility across operations

This holistic model benefits sectors ranging from consumer electronics and medical devices to aerospace, industrial IoT, and telecommunications.

Concept-to-Scale EMS: A Strategic Advantage

A hallmark of best-in-class manufacturing partners is their ability to offer concept-to-scale EMS services — translating early product ideas into manufacturable designs and then scaling production to meet global demand. East West Manufacturing exemplifies this approach by delivering a tightly integrated suite of capabilities that align engineering vision with manufacturing execution.

Early Stage: Design Collaboration and Prototyping

During the initial stages of product development, design expertise is paramount. Collaborative engineering teams work with clients to refine product specifications, optimize for manufacturability, and anticipate supply chain needs. Services like electrical design engineering — critical in defining circuit architectures and electronic systems — ensure that products are efficient, compliant, and ready for production.

Additionally, specialized resources such as electrical engineer design support allow companies to leverage experienced engineering talent without expanding internal teams — a significant advantage for emerging brands with constrained resources.

Rapid prototyping follows design, turning concepts into physical units for testing, validation, and demonstration. This iterative process helps surface potential issues early — reducing costly revisions later.

Integrated Manufacturing Services

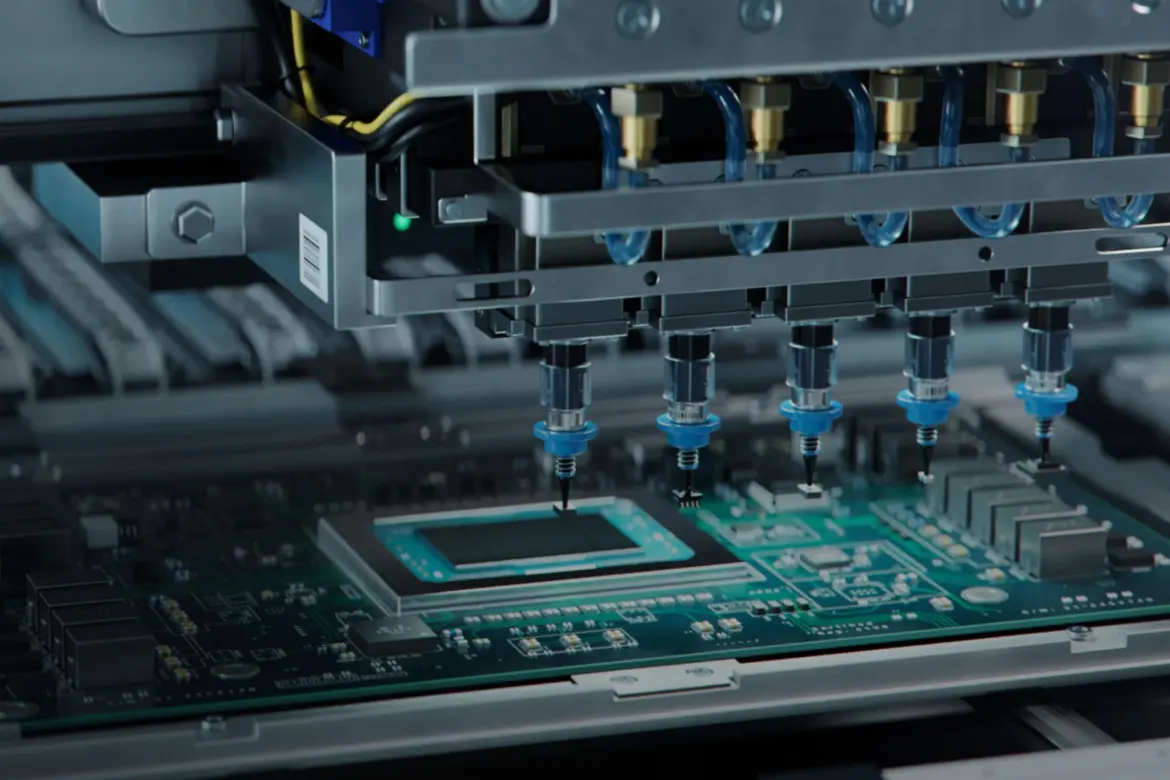

When a design is ready for production, the focus shifts to manufacturing excellence. Electrically complex products require meticulous assembly, precise component placement, and robust testing protocols. Top EMS providers manage:

- PCB assembly and surface mount technology (SMT)

- Through-hole and mixed technology assembly

- Automated optical inspection (AOI)

- Functional testing and validation

- Firmware programming and final system integration

By consolidating these services under one roof — as East West Manufacturing does — brands benefit from continuity of quality, reduced lead times, and improved communication among teams.

Procurement and Supply Chain Management

One of the greatest challenges in electronics manufacturing is supply chain complexity. Components may come from dozens of suppliers across multiple continents, each subject to lead times, tariffs, quality variability, and geopolitical risk. End-to-end solutions incorporate advanced supply chain management to:

- Source components strategically to balance cost and reliability

- Predict disruptions using data analytics and alternative sourcing

- Manage inventory efficiently to minimize excess stock or shortages

- Coordinate global logistics for on-time delivery

This holistic oversight means that potential bottlenecks can be anticipated and resolved long before they threaten production schedules.

Quality, Compliance, and Regulatory Assurance

Products destined for global markets must adhere to a range of standards — from FCC, CE, RoHS, and REACH in electronics to industry-specific certifications in medical, automotive, or defense applications. End-to-end partners embed compliance into every step, minimizing risk and ensuring that finished products meet or exceed regulatory expectations.

Comprehensive quality systems, traceability from components to finished goods, and rigorous testing protocols form the backbone of dependable manufacturing.

Retail Packaging and Fulfillment

Once manufacturing is complete, how products are presented and distributed matters just as much as how they were built. A retail packaging solution is an integral piece of the supply chain puzzle — encompassing design, materials, labeling, and distribution models that align with brand positioning and customer expectations.

Effective retail packaging not only protects the product during transit but also enhances consumer perception, supports sustainability goals (e.g., recyclable materials), and complies with regional marking or safety standards.

Sustaining Competitive Advantage Through Partnership

In an industry where innovation cycles are shrinking and customer expectations are rising, companies that rely on fragmented suppliers often lose ground to competitors with unified, strategic manufacturing partners. The advantages of end-to-end solutions are unmistakable:

• Predictable Performance

Integrated design, manufacturing, and logistics reduce variation and increase predictability, allowing teams to plan with confidence.

• Faster Innovation

From prototype to production launch, synchronized workflows speed up iteration and accelerate learning.

• Scalable Infrastructure

Whether producing hundreds or hundreds of thousands of units, cohesive processes support expansion without disruption.

• Cost Efficiency

By optimizing each stage of production and logistics in tandem, companies reduce waste, avoid duplication, and unlock economies of scale.

Case in Point: East West Manufacturing

East West Manufacturing stands as a leading example of how end-to-end solutions empower brands across industries. Their concept-to-scale EMS services facilitate seamless collaboration from early design and engineering to manufacturing, testing, packaging, and global supply chain execution. By aligning technical expertise with operational excellence, they enable both established global brands and agile emerging innovators to deliver high-quality products on time and within budget.

Whether it’s supporting detailed electrical design engineering work, helping with specialized electrical engineer design needs on complex electronic systems, or integrating advanced logistics and compliance services, East West Manufacturing delivers the infrastructure modern companies need to thrive in competitive markets. Partnering with a provider like this transforms manufacturing from a cost center into a strategic asset.

The Future of Electronics Manufacturing

Looking ahead, end-to-end solutions will continue to evolve as technology, data integration, and global dynamics shift. Advancements in automation, real-time supply chain analytics, AI-enabled quality control, and digital twin simulations promise even greater precision and agility. Companies that invest in unified manufacturing platforms today are positioning themselves to lead in the markets of tomorrow.

For electronics brands seeking to innovate smarter, scale faster, and compete globally, an end-to-end approach isn’t just beneficial — it’s essential.